Architects: Want to have your work featured on Architizer? Upload your projects to be considered for an editorial feature! Don’t forget to sign up for our inspirational newsletter.

Museums rarely break with tradition. Designed as hermetic structures built to protect and enclose, museums have been slow to change throughout history. Enter the Jan Shrem and Maria Manetti Shrem Museum of Art, by SO – IL and Bohlin Cywinski Jackson.

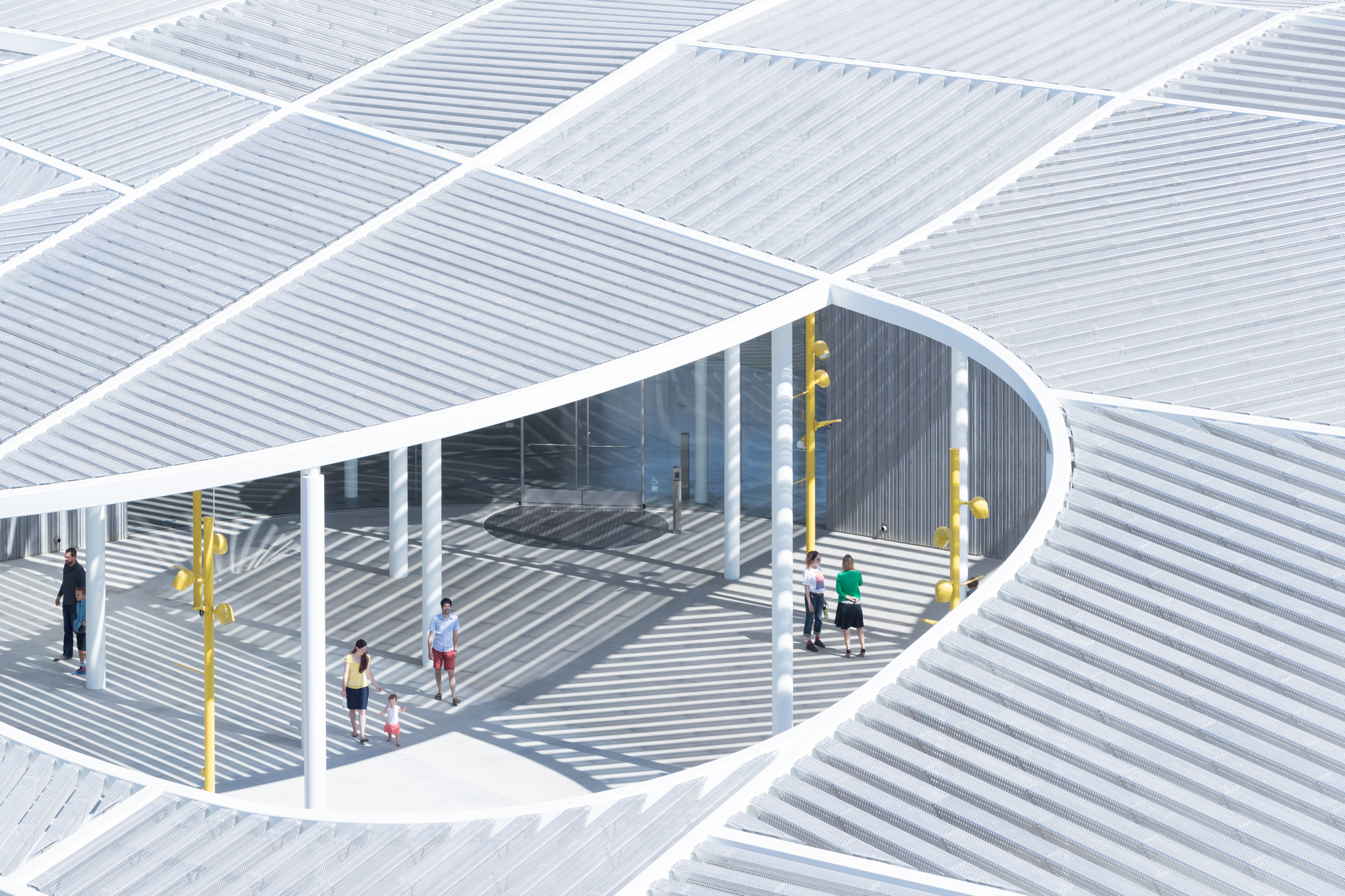

Constructed in California’s Central Valley, the Manetti Shrem was designed to challenge convention as the first purpose-built museum at UC Davis. The concept was derived as “a patchwork of geometric forms that refers to the agricultural landscape and the vast horizon.” Made to be flexible and integrate with the surrounding site, the design was proposed as a new idea for the museum of the future.

Florian Idenburg, founding partner of SO – IL, described the project as “neither isolated nor exclusive, but open and permeable; not a static shrine, but a constantly evolving public event.” Integrating indoors and outdoors, the project was organized with porous and flexible spaces to appreciate art.

The design includes pavilions for art making, galleries and operations, as well as a courtyard, lobby and entry plaza. The single-story structure features a clover-shaped plan with the interior courtyard filling the space between the office and gallery wings. Through material, form and envelope, the project signifies a new direction for museum design. Read on to discover the manufacturers that brought the Manetti Shrem to life.

Aluminum Canopy

Manufactured by Front Inc

As the signature element of the Manetti Shrem, the 50,000 square-foot “Grand Canopy” of perforated aluminum louvers were manufactured by Front Inc. Supported by 40 steel columns, this graceful canopy features a sloping white wave of custom marine grade aluminum. The permeable roof helps control lighting and shade to create new spaces for informal learning. Front developed the canopy for high light permeability and free spans up to 35ft. The optimized canopy was made with 1/8 inch thick aluminum with up to 40% open perforation area. The result is an integrated, elegant structure of 910 beams with unique offcuts and splice locations.

Interior Ceilings

Interior Ceilings

Manufactured by Armstrong

Combining acoustical ceilings with an interior suspension grid, the ceilings by Armstrong were made to be both simple and restrained. Because the museum’s permanent collection includes many sensitive works on paper, the galleries had to be designed to be completely artificially lit. The ceilings are made to integrate with the lighting approach while allowing moments of natural daylighting. The galleries themselves are arranged as a variety of flexible spaces, with the larger gallery capped by extruded aluminum panels, with ductwork and piping above. Lower ceilings in ancillary spaces feature the texture of the ceiling panels with changing orientation as they align with the axis of the room.

Structural System

Structural System

Manufactured by Olson Steel

Created with a braced frame structure to integrate with the canopy steel, the structural supports for Manetti Shrem were manufactured by Olson Steel. Steel was chosen to accommodate the pavilion’s irregular shapes, long spans, and thin, elegant aesthetic. The pavilions use composite deck diaphragms supported by steel girders and beams, with steel columns bearing on spread footings and grade beams. Located in a high seismic zone, the project was built with buckling-restrained braced frames (BRBFs) that serve as the lateral force-resisting system. For the exterior, beams and girders were rolled into complex curves to support the canopy’s varying arrays and patterns.

Glazing & Curtain Walls

Glazing & Curtain Walls

Manufactured by Front Inc. and Oldcastle

The museum’s glazing required innovative detailing and support to hold the 14ft tall, curved glass walls. Built with laminated glass by Front and curtain walls by Oldcastle, the frameless glass walls were made with custom components to design for seismic movements, as well as make for more precise installation with flush aligned glass joints. The glazing opens up to views of the canopy and surrounding landscape, including an interior court below a large, oblong oculus. This space includes a blank wall for film projection, standing in contrast with the glazing and other delicate and intricately combed precast concrete. The entry courtyard speaks to this condition through a fully enclosed portion of the building with a convex section of glass wall.

Precast Concrete

Precast Concrete

Manufactured by CTU Precast

Beyond the structure, interiors and glazing, the single-story museum structure was wrapped in rippling pre-cast concrete. The custom-design formliner by CTU Precast features subtle detailing and patterns. The textured materials, from aluminum and glass to wood and concrete, was made to complement the Central Valley’s soft light. The exterior corrugated concrete panels range as high as 32ft, while 8,000 square feet of galleries feature polished-concrete floors. The panels by CTU come in different widths and varying heights and thickness, depending on the building height and applied loads.

Architects: Want to have your work featured on Architizer? Upload your projects to be considered for an editorial feature! Don’t forget to sign up for our inspirational newsletter.